Physically, chemically and mechanically, aluminum is a metal like steel, metal, copper, zinc, lead, or titanium. It tends to be softened, projected, framed, and machined likewise to these metals and conveys electric flows. Indeed, regularly similar hardware and manufacturing strategies are utilized concerning steel. Bullion pipes are one of the leading suppliers of aluminum wires.

Light Weight

Aluminum is an extremely light metal with a particular load of 2.7 g/cm3, about 33% of that of steel. This reduces the expenses of assembling with aluminum. Once more, its utilization in vehicles decreases dead-weight and energy utilization while expanding the load limit. This likewise lessens commotion and improves comfort levels.

Its solidarity can be adjusted to the application needed by changing the organization of its composites. Aluminum-magnesium-manganese composites are an ideal blend of formability with strength, while aluminum-magnesium-silicon combinations are ideal for auto body sheets, which show great age-solidifying when exposed to the heat on artwork.

Erosion Resistance

Aluminum normally creates a defensive meager oxide covering which holds the metal back from connecting with the climate. It is especially valuable for applications where it is presented to eroding specialists, as in kitchen cupboards and in vehicles. All in all, aluminum amalgams are less erosion safe than unadulterated aluminum, with the exception of marine magnesium-aluminum composites. Various sorts of surface treatment, for example, anodising, painting or lacquering can additionally improve this property.

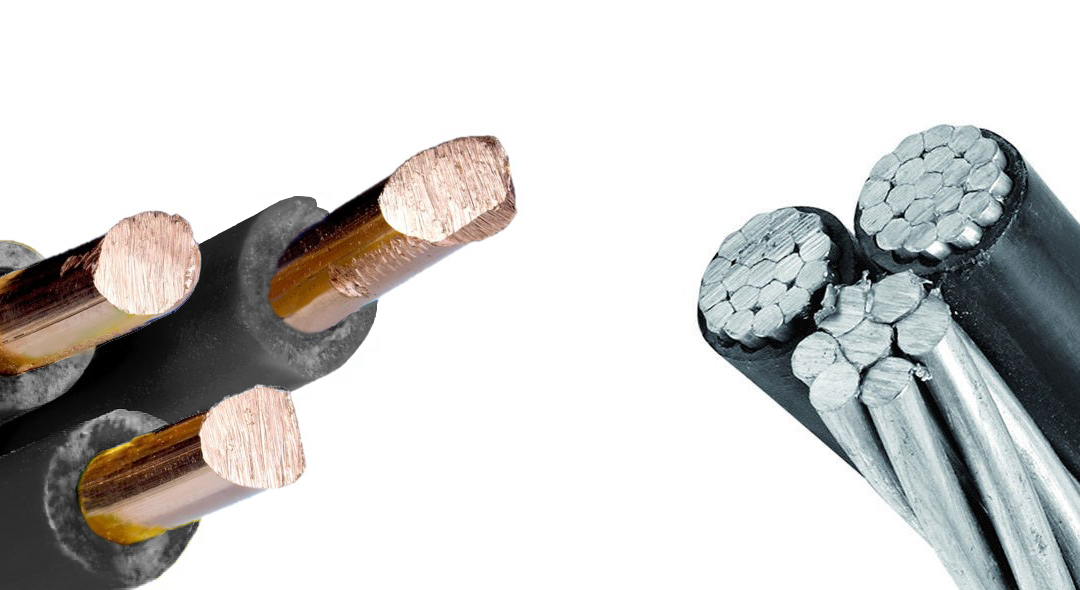

Electrical and Thermal Conductivity

Aluminum is an incredible warmth and power conveyor and corresponding to its weight is twice as great a channel as copper. This has settled on aluminum as the best option for significant force transmission lines. It is additionally a sublime warmth sink for some applications that expect warmth to be depleted away quickly, for example, in PC motherboards and LED lights.

On the off chance that aluminum is utilized as a conveyor material, its lower conductivity requires a wire size that is around 33% bigger than that of a copper wire. Eventually, be that as it may, the protecting material utilized with the wire assumes a pivotal part in presentation; an aluminum wire can have a similar current conveying limit as an H07RN-F copper wire. Aluminum’s bigger wire size would just be a hindrance in applications requiring tight separating, for example, when introduced in thickly stuffed control cupboards. Current realities for aluminum represent themselves with regards to the issue of weight. As a crude material, aluminum is around 70% lighter in weight than copper. This can be useful in the endeavors of various application fields hoping to lessen the heaviness, everything being equal. Normally, when utilized in electrical links, the lower weight makes them simpler to introduce. High-voltage links have for some time been produced using aluminum; the lighter weight decreases the malleable power put on wire and poles essentially. However, even enterprises, for example, auto-intention producing and the avionic business is changing to aluminum wires. All the link bridles in the Airbus A380 are as of now made of aluminum. Aluminum wires can be up to 60% lighter than copper wire with a similar current-conveying limit. In any event, for applications that require adaptable link associations, copper should not generally be the best option.

Reflectivity

Aluminum is a decent reflector of obvious light just as warmth, and that along with its low weight, makes it an ideal material for reflectors in, for instance, light fittings or salvage covers. Cool rooftops made of covered aluminum are important in decreasing inner sun oriented warmth inside a house, by reflecting up to 95% of daylight.

Pliability

Aluminum is flexible and has a low dissolving point and thickness. It tends to be prepared in a few different ways in a liquid condition. Its malleability permits aluminum items to be shaped near the finish of the item’s plan. Regardless of whether sheets, foil, mathematical setups, cylinders, bars or wires, aluminum is up to them all.

Strength at Low Temperatures

As opposed to steel, which quickly gets fragile at low temperatures, aluminum shows expanded elasticity as temperatures drop.

Impermeable and Odorless

Aluminum foil is just 0.007 mm in thickness, yet is as yet solid and totally impermeable, keeping any food enclosed by it liberated from outer tastes or scents. It keeps out bright beams also.

Also, the actual metal is non-harmful and scentless, which makes it ideal for bundling touchy items like food or drugs. The way that reused aluminum can be utilized lessens the carbon impression for this phase of food and refreshment producers too.

Non-attractive

Aluminum is non-attractive, making it valuable for electrical shieldings as in PC plates, dish recieving wires, busbars or magnet lodgings.

Non-harmful

Aluminum is non-poisonous and is utilized to make woks, pressure cookers, and numerous other cooking tools unafraid. It is handily cleaned and doesn’t taint the food at any stage.

Sound and Shock Absorption

Aluminum is a brilliant sound safeguard and is utilized for developing roofs. It is additionally utilized in auto guards because of its stun retaining properties.

Non-sparking

Aluminum delivers no sparkles when it comes into contact with itself or non-ferrous metals.

Recyclability

Aluminum is 100% recyclable and reused aluminum is indistinguishable from the virgin item. This makes it a substantially more financially savvy source material for creation runs. The re-liquefying of aluminum requires little energy: just about 5% of the energy needed to deliver the essential metal at first is required in the reusing interaction.